Services

TRADE

Our Hygienic Product Range

-

Baby Diapers

ButtonOur baby diapers are crafted with utmost care, keeping your little ones comfortable and dry. With superior absorbency and a snug fit, our diapers ensure that your baby can move freely and explore the world with a smile.

-

Adult Pants

ButtonWe understand the importance of dignity and confidence, regardless of age. Our adult pants offer discreet and reliable protection, allowing individuals to maintain an active lifestyle with comfort and assurance.

-

Bed Sheets

ButtonEnjoy a restful and hygienic sleep with the premium bed sheets. Designed for softness and durability, our bed sheets provide the perfect touch to enhance your sleeping experience.

-

Sanitary Napkins

ButtonEmpowering women with reliable protection, our sanitary napkins are designed with advanced technology and superior absorbency. Feel confident and at ease during your menstrual cycle with our thoughtfully crafted products.

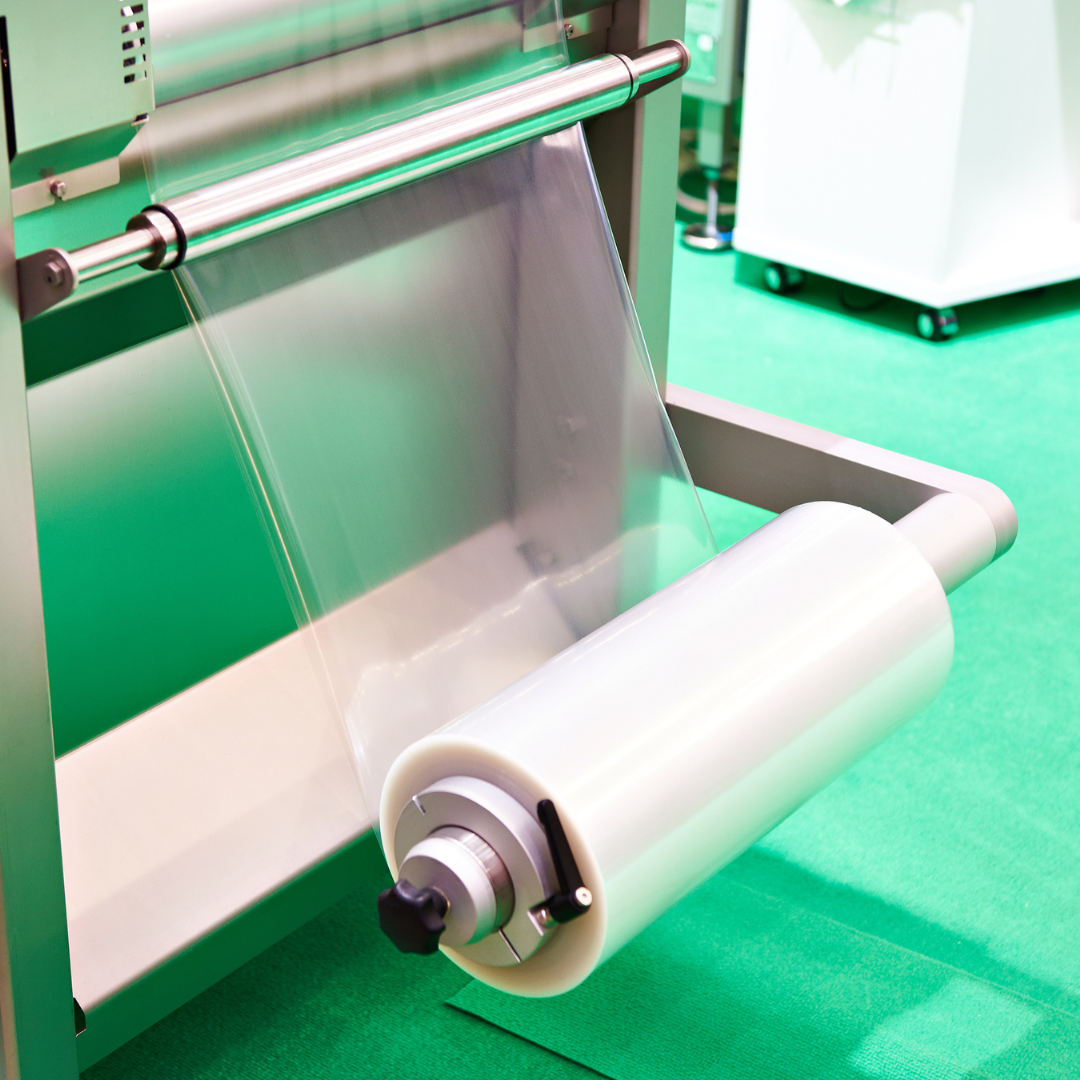

PRODUCTION

Beyond our hygienic product range, we are committed to making a positive impact on the environment. Our state-of-the-art plastic recycling facility allows us to obtain valuable polypropylene (PP) and polyethylene (PE) from plastic waste. Through responsible recycling practices, we contribute to reducing plastic waste and conserving valuable resources.

-

Plastic Recycling - PP

Button

"PP" stands for "Polypropylene." Polypropylene is a thermoplastic polymer that is used in various applications due to its durable, lightweight, and chemical-resistant properties. PP is widely utilized in packaging, automotive parts, medical supplies, household items, textile products, and many other fields.

Polypropylene is preferred for the following reasons:

Lightweight: PP material is very lightweight, enhancing portability and ease of use for products.

Chemical Resistance: PP exhibits resistance to various chemicals, making it suitable for storing or transporting chemical products or liquids.

High Fiber Strength: It is favored for textile products and weaving materials due to its high strength and durability.

Low-Density Plastic: PP is a low-density plastic material, contributing to lightweight products and energy efficiency.

Tensile Strength: PP possesses high tensile strength, making it suitable for applications requiring strength.

In the plastic industry, PP is used with various manufacturing methods such as injection molding, extrusion, and blow molding to create a wide range of products.

-

PE

Button

"PE" stands for "Polyethylene." Polyethylene is one of the most widely used types of plastics and is utilized in various applications in different forms. PE is commonly employed in packaging, coating materials, pipes, containers, toys, water bottles, and many other products.

Polyethylene is preferred for various reasons:

Available in Various Types: Polyethylene comes in different types with varying densities and properties. These types include High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE), each used for different applications.

Flexibility and Strength: Low-Density Polyethylene like LDPE offers flexibility and impact resistance, while HDPE can provide higher strength properties.

Chemical Resistance: Polyethylene exhibits resistance to chemicals and solvents.

Heat Resistance: Polyethylene is commonly used in applications that require low-temperature tolerance and heat insulation.

Low Water Absorption: Polyethylene is suitable for products that come into contact with water due to its low water absorption rate.

Polyethylene is used in the manufacturing of a wide range of products through various molding and production methods. Plastic bottles, bags, toys, packaging materials, agricultural products, and more can be produced using polyethylene.